In the intricate world of modern industrial automation and smart hardware, a high-speed motor alone often fails to meet the direct needs of an application. The raw power output of a motor typically features high rotation speeds but low torque, which is suboptimal for devices requiring precise control, high thrust, or smooth low-speed operation. This is where the Small Gear Motor, a perfect fusion of a motor and a gearbox, steps in as the “power translator.” As a professional manufacturer, Yuyao Hongyang Micromotor Co., Ltd. is dedicated to solving core pain points—from torque amplification to speed conversion—through precision machining and material innovation, providing a stable and reliable “heart of power” for global clients.

The Art of Balancing Torque and Speed: How Do Small Gear Motors Achieve Efficient Transmission?

The core logic of a small gear motor lies in “reducing speed to increase torque.” Physics dictates that power is the product of torque and angular velocity. Given a constant input power, reducing the rotational speed through a reduction mechanism allows for a proportional increase in output torque. This is the secret behind how small-scale devices can drive heavy loads.

Yuyao Hongyang Micromotor Co., Ltd. maintains nearly rigorous requirements for transmission efficiency during the production process. A superior gear motor must not only be “powerful enough to drive the load” but also “efficient enough to save energy.” In our R&D laboratories, our engineers focus on three key dimensions:

First is the scientific matching of multi-stage gear structures. Depending on the required reduction ratio, we flexibly employ planetary gear, spur gear, or worm gear structures. Planetary gears, in particular, are favored for their ability to share loads across multiple planet gears, providing maximum output torque and higher structural rigidity within the same volume. For portable medical devices where space is at a premium, the micro-planetary reduction solutions developed by Yuyao Hongyang Micromotor Co., Ltd. can output several kilograms of thrust within a millimeter-scale footprint.

Second is the deep optimization of energy loss. Every stage of gear contact generates frictional heat and mechanical loss. By optimizing the involute profile design of the gear teeth, Hongyang significantly reduces relative sliding during meshing, ensuring that our comprehensive transmission efficiency remains at the forefront of the industry. This means that in battery-powered applications, such as smart locks or robot joints, our motors can substantially extend the device’s standby time.

Finally, we implement a differentiated material application strategy. For different workloads and environments, we provide hybrid configurations of metal gears and high-strength engineering plastic gears (such as POM or PEEK). Metal gears handle the high torque impact at the final stage, while the primary high-speed stages utilize self-lubricating plastic gears. This ensures strength while effectively reducing operational noise—a critical factor in smart home applications like automated curtains or sit-stand desks.

From Machining to Assembly: How Does a Professional Gear Motor Factory Define Precision?

The quality of a gear motor is often determined by micron-level differences invisible to the naked eye. As a veteran Small Gear Motor Factory, Yuyao Hongyang Micromotor Co., Ltd. understands that manufacturing craftsmanship is the foundation of performance. In the world of micromotors, an error of just 0.01mm can double the operational noise or even slash the service life by 50%.

To ensure that the gearbox does not suffer from “tooth skipping,” “uneven wear,” or “jamming” during long-term operation, our factory has established a life-cycle precision control system:

High-Precision Machining Capabilities: For metal gears, we utilize precision CNC gear hobbing machines, where the module can be accurate to 0.1 or even smaller. For plastic gears, we employ high-precision constant-temperature injection molding. Yuyao Hongyang Micromotor Co., Ltd. has invested heavily in advanced gear testing instruments capable of full-scale scanning of cumulative pitch error and tooth profile error, ensuring every component meets the design preset.

Excellence in Noise Control Engineering: Noise usually stems from shaft misalignment or excessive gear backlash. Hongyang utilizes fully automated assembly lines integrated with visual alignment technology to ensure that the coaxiality deviation between the motor shaft and the gearbox input remains within an extremely small range. Furthermore, we optimize the acoustic characteristics of the gearbox casing, using reinforced rib designs to suppress resonance and eliminate abnormal vibrations at the source.

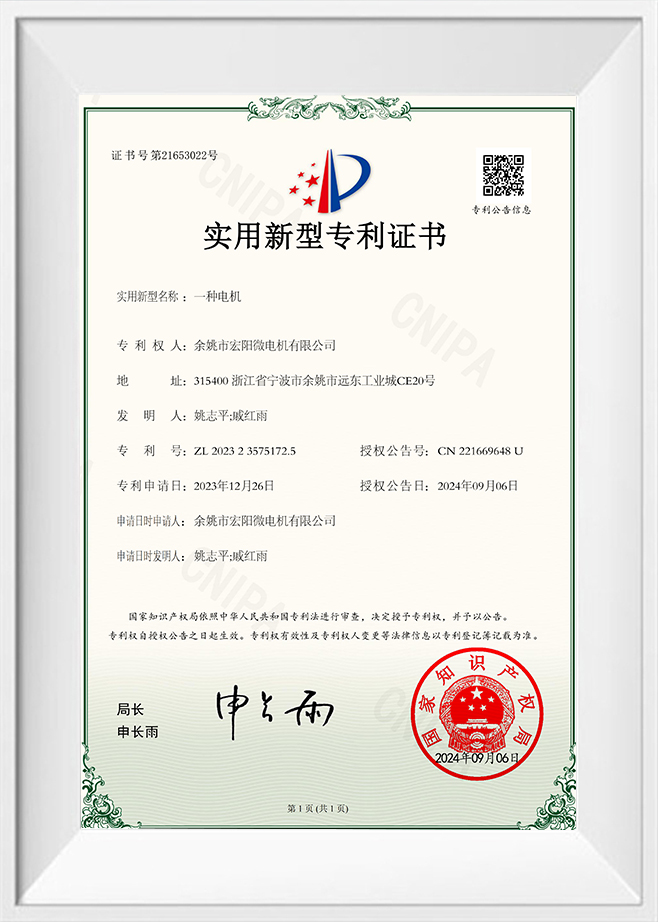

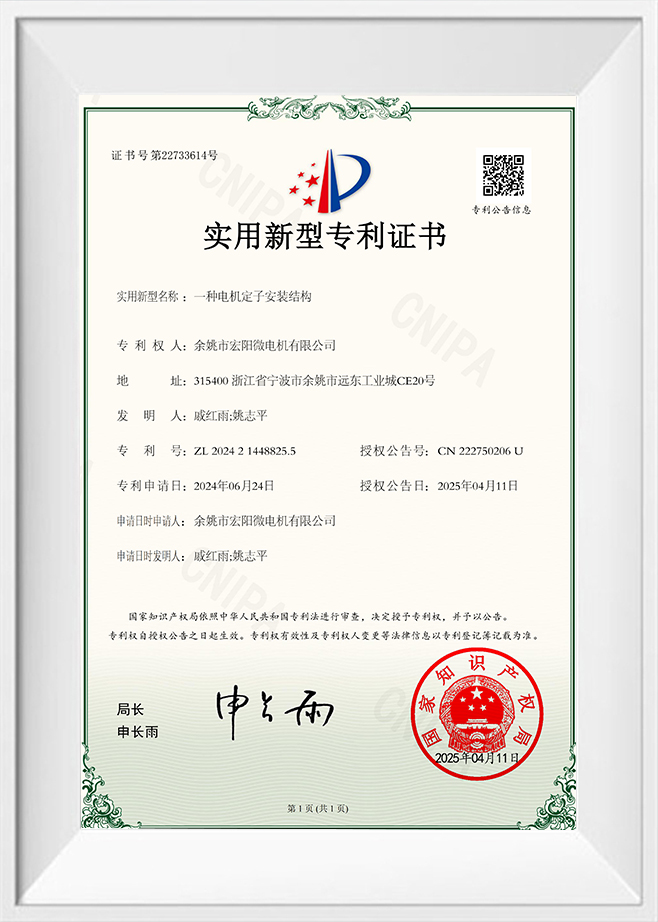

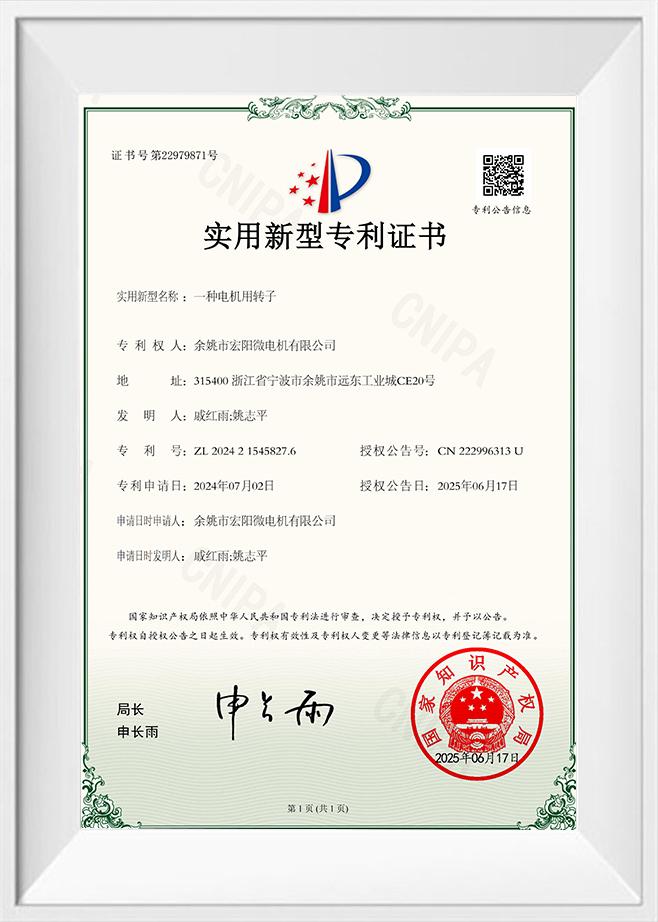

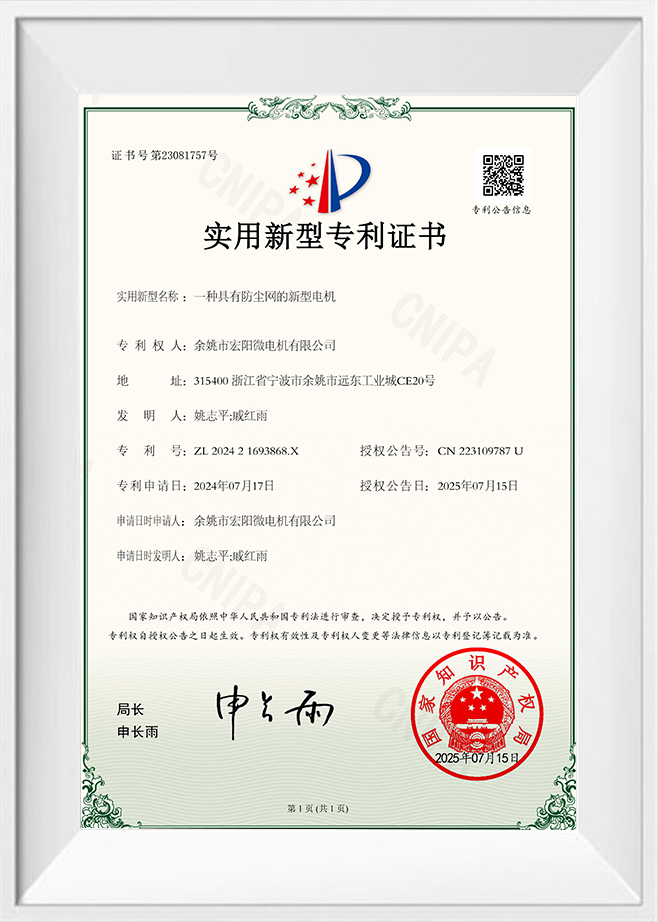

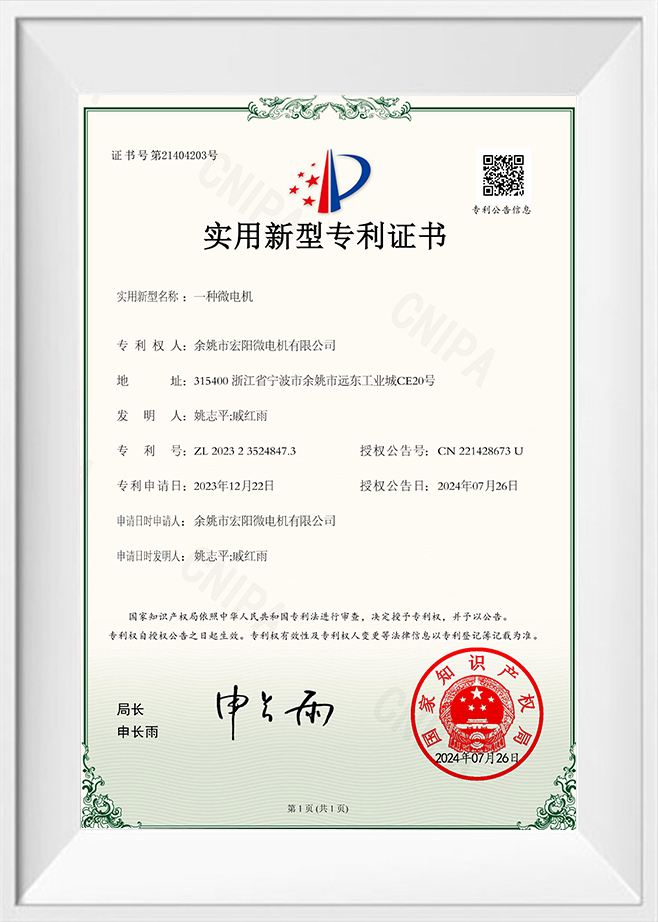

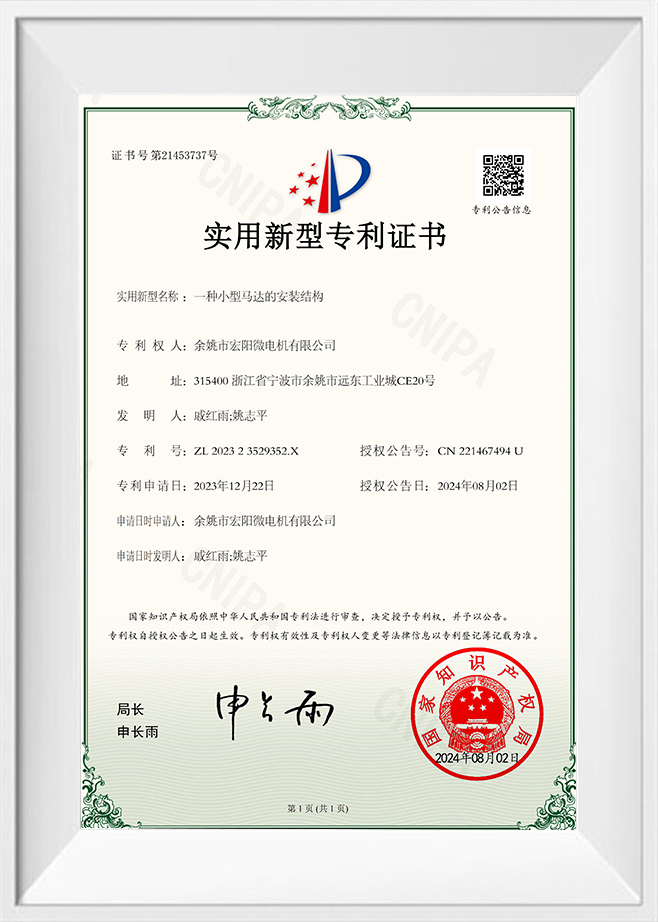

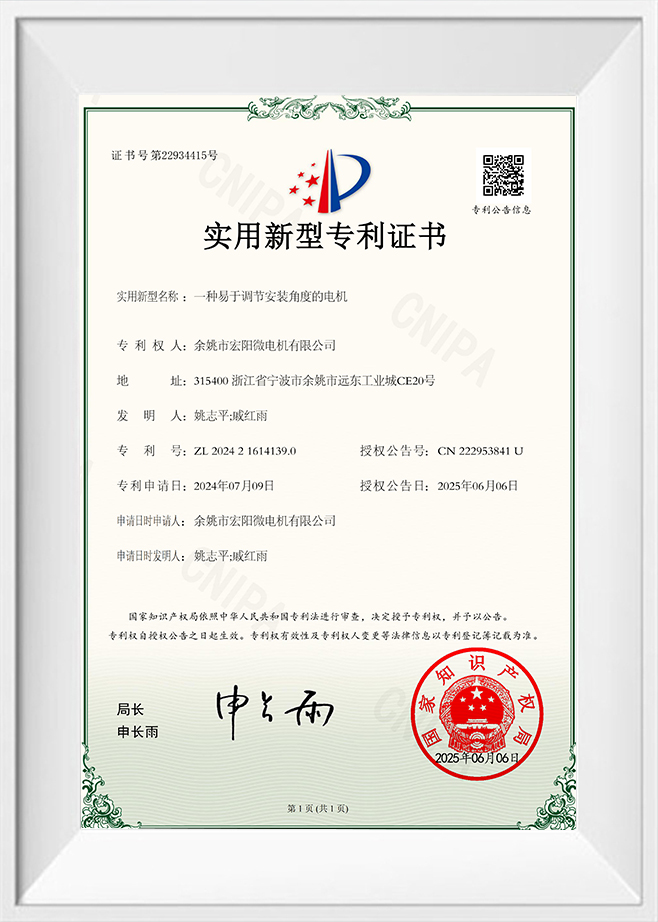

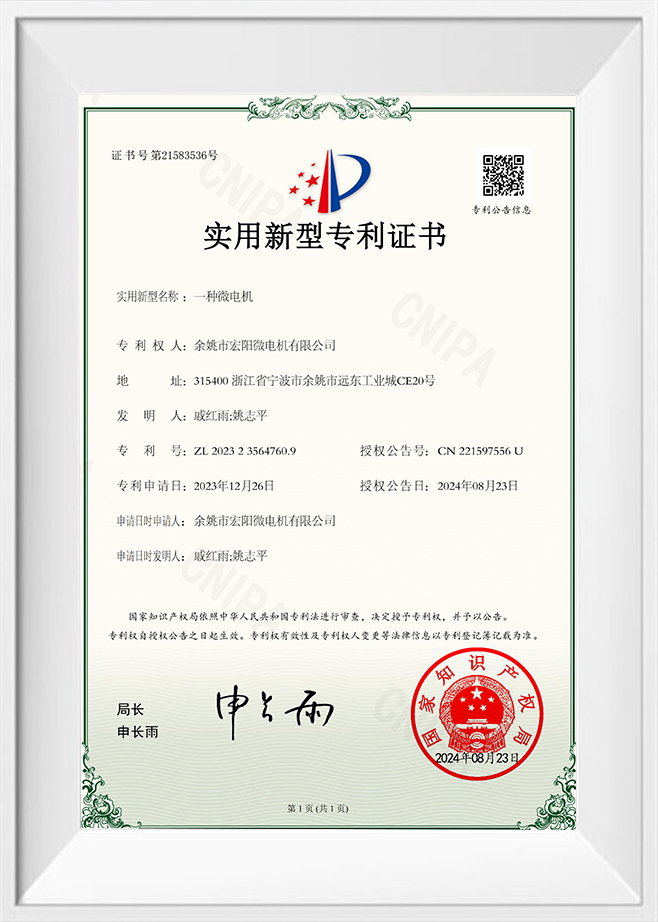

Strict Lubrication and Sealing Standards: The lifespan of a gear motor depends heavily on the stability of its lubricant. We select specific long-life synthetic greases based on different operating temperature ranges (from -40°C to +120°C). These greases offer excellent adhesion and shear resistance. Combined with the patented sealing structures of Yuyao Hongyang Micromotor Co., Ltd., we effectively prevent oil leakage and the intrusion of external dust, ensuring the motor maintains stable operation for years in harsh conditions without manual maintenance.

Deep Adaptation of Application Scenarios: How to Choose the Best Gear Motor Solution for You?

The charm of small gear motors lies in their incredibly wide range of adaptability. From the precision cash-out systems in ATMs to micro-peristaltic pumps in laboratories, and steering systems for AGVs in factory automation, every application has vastly different requirements for torque, speed, noise, and volume.

To help global customers select products accurately and reduce R&D risks, Yuyao Hongyang Micromotor Co., Ltd. has summarized a decision-making model based on application dimensions. We involve ourselves in the customer’s R&D process at an early stage, providing one-stop technical support from torque verification to life-cycle simulation.

Below are typical selection recommendations from Hongyang Micromotor for several core industries:

| Industry Focus |

Recommended Solution |

Hongyang Technical Support |

Typical Application |

| Extreme Space Constraints |

Micro Planetary Gear Motor |

Diameters as low as 6mm-10mm, multi-stage options |

Micro medical pumps, lens zoom |

| Ultra-Low Noise Operation |

Helical/Special Plastic Gear Combo |

Optimized meshing overlap, silent grease filling |

Smart shading, office automation |

| High Load & Frequent Start/Stop |

All-Metal Reinforced Gearbox |

Vacuum heat-treated high-carbon steel gears |

Industrial valves, vending machines |

| Precise Position Control |

Integrated Encoder Gear Motor |

Supports FOC closed-loop control, high pulse accuracy |

Collaborative robot joints, gimbals |

Yuyao Hongyang Micromotor Co., Ltd. provides not only standardized gear motor products but also strong OEM/ODM rapid response capabilities. Our engineering team understands that standard products often cannot cover all specialized needs. Whether it is a custom D-shaped output shaft, a specific reduction ratio, or an IP65 protection rating for harsh environments, we can complete solution verification and provide sample test reports in a short timeframe.

As your core supplier, Hongyang Micromotor consistently adheres to driving quality through technological innovation. In the future of intelligence, we will continue to explore the application of lightweight alloys and smarter motor health monitoring algorithms, ensuring that every motor labeled “Hongyang” operates stably in automated equipment worldwide.

Eng

Eng  русский

русский Español

Español