Project Background

An electric angle grinder works as both an industrial tool and a practical household maintenance tool. It relies on a DC motor as its core drive component, which spins grinding or cutting discs at high speed to get the job done. It’s mainly used for cutting, grinding and polishing hard materials like metal, stone and concrete, finding wide application in construction, auto maintenance, general industrial processing and household repairs. Thanks to its easy operation and strong power, it handles both light and heavy workloads with ease, becoming a must-have tool for industrial production, decoration projects and daily home maintenance.

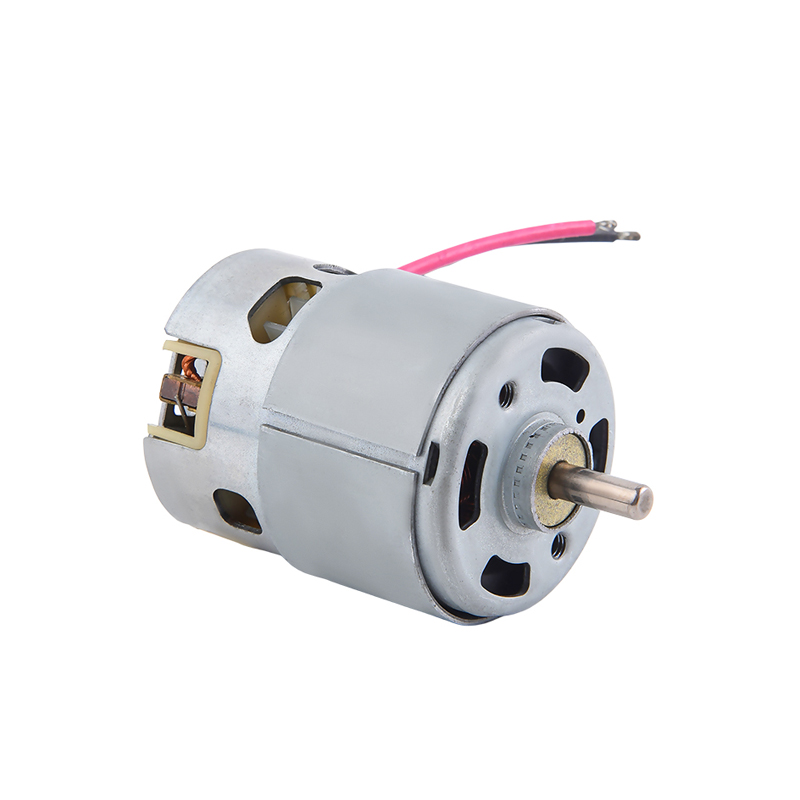

But as the core drive part, the motor has a direct impact on the angle Grinder’s performance. Low-quality motors tend to suffer from issues like unstable speed, insufficient torque (which hurts grinding and cutting accuracy), severe overheating (cutting down continuous working time and raising safety risks), loud noise and short service life. These problems mean frequent maintenance and replacements, driving up operating costs. In the worst cases, motor failure can even ruin the entire machine, greatly hampering work efficiency and user experience. Today we’ll dive into DC motor drive solutions for electric angle grinders, with a focus on HongYang Motor's RS-885 model. We’ll break down its working principle, key features and practical applications.

Eng

Eng  русский

русский Español

Español