The Evolution and Mechanics of Small DC Motors in Modern Industry

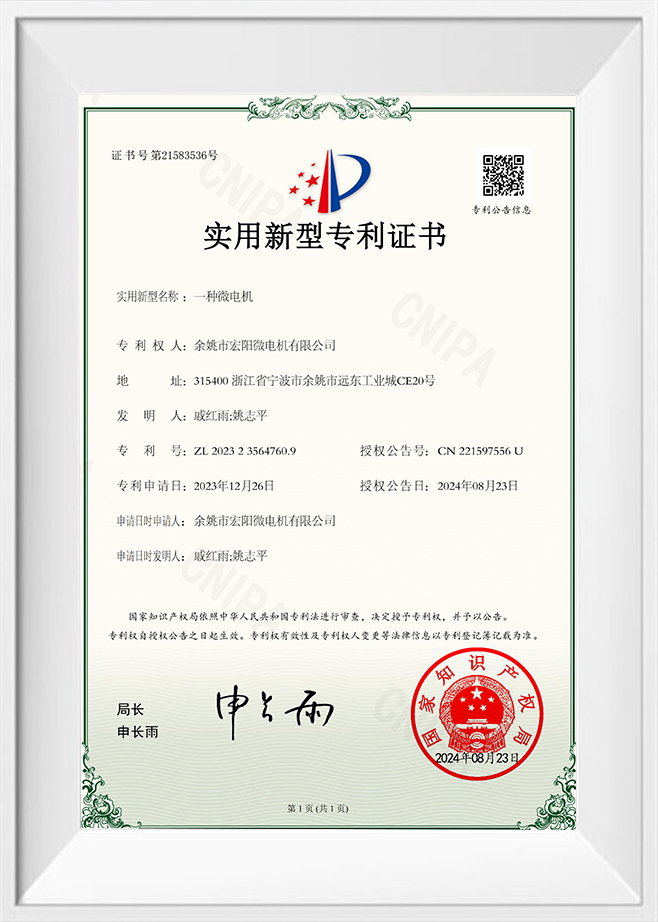

The landscape of modern electromechanical engineering has been fundamentally reshaped by the drive toward miniaturization. At the center of this movement is the small DC motor, a device that converts direct current electrical energy into mechanical rotation with increasing efficiency and decreasing footprints. For over three decades, Yuyao Hongyang Micromotor Co., Ltd. has been at the forefront of this evolution. Founded in 1988 as the first miniature motor factory in its city, Hongyang has witnessed the transition from basic analog toys to sophisticated smart home ecosystems, providing the “heartbeat” for millions of devices worldwide.

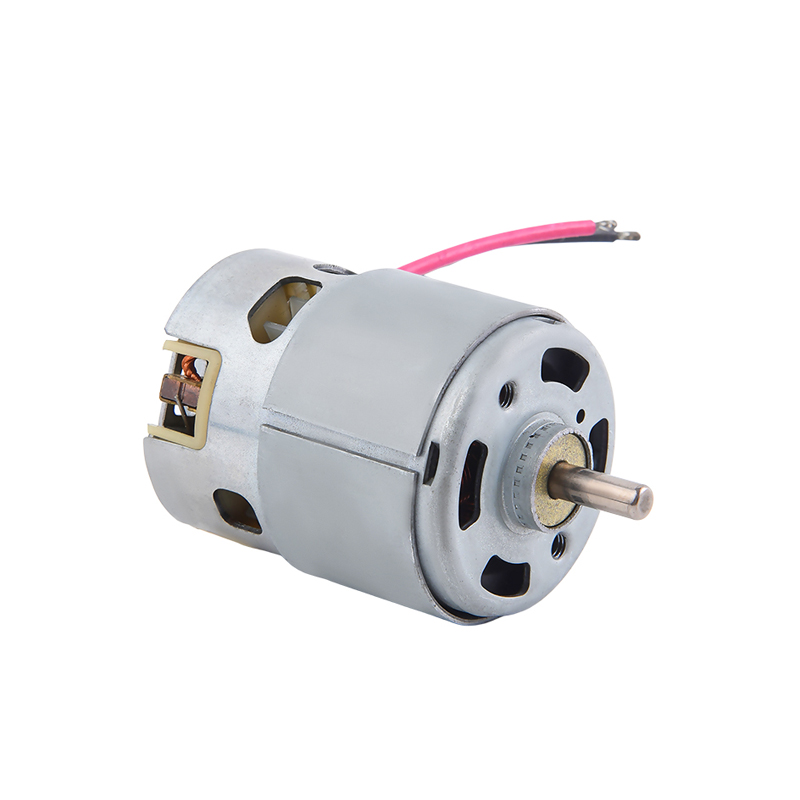

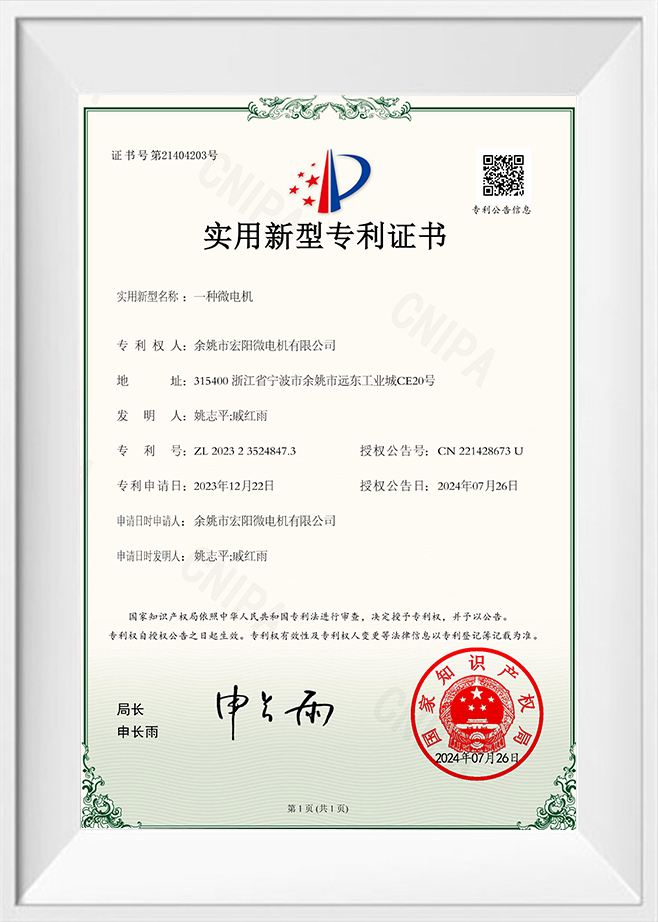

The fundamental physics of a small DC motor rely on the interaction between magnetic fields and electrical conductors. When a current passes through the armature coil within a magnetic field, the Lorentz force generates torque, causing the rotor to spin. While the principle remains constant, the execution has become incredibly refined. At Yuyao Hongyang Micromotor Co., Ltd., our R&D teams focus on optimizing the magnetic circuit design and winding density. By utilizing high-grade permanent magnets and high-purity copper wiring, we ensure that even our smallest motors deliver high torque-to-weight ratios.

To give our partners a clearer view of our diverse manufacturing capabilities, the following table outlines the core parameters of our primary product series:

| Motor Series |

Primary Applications |

Typical Voltage Range |

Key Performance Features |

| 300 Series |

CD players, precision toys, fragrance dispensers |

1.5V – 12V |

Ultra-low noise, high stability |

| 500 Series |

Blood pressure monitors, smart locks, alarms |

3.0V – 24V |

Low current, long lifespan |

| 700 Series |

Power tools, vacuum cleaners, garden sprayers |

6.0V – 36V |

High power density, high torque |

| 800 Series |

Industrial pumps, automotive actuators |

12V – 24V |

Heavy-duty durability, heat resistance |

| 900 Series |

High-end power tools, specialized machinery |

12V – 48V |

Maximum torque output, rugged build |

The manufacturing process at Hongyang is a testament to industrial excellence. Occupying over 10,000 square meters, our facility integrates the entire industrial chain—from raw material processing to final assembly. This end-to-end control allows for meticulous quality oversight, ensuring that every motor leaving the line meets the rigorous demands of the global market. Our 30-year legacy isn’t just about time; it’s about the accumulated expertise of hundreds of technical professionals who understand how to balance rotational speed, stall torque, and heat dissipation in a compact housing.

Engineering Excellence: Customization and Large-Scale Production

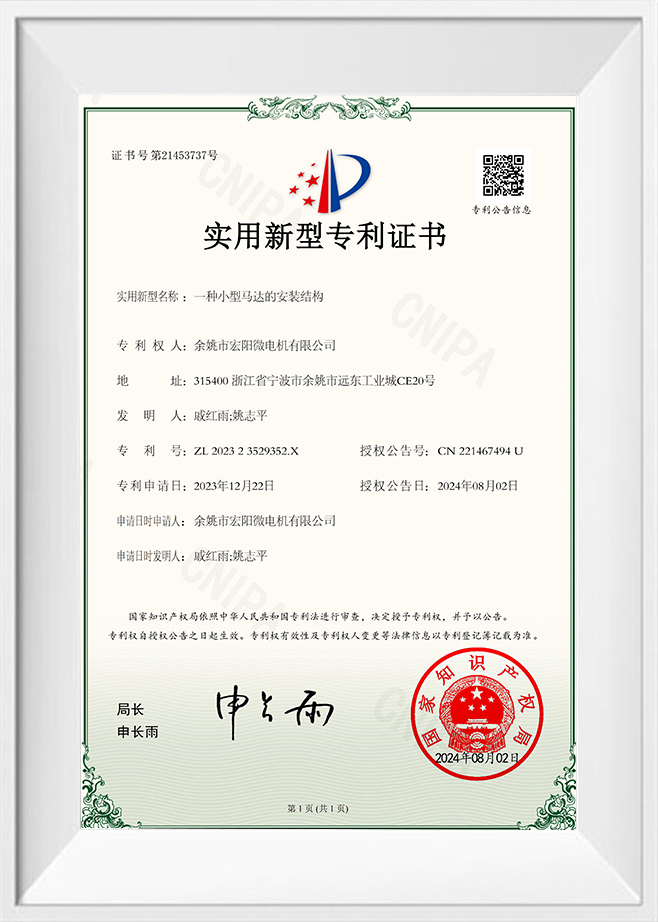

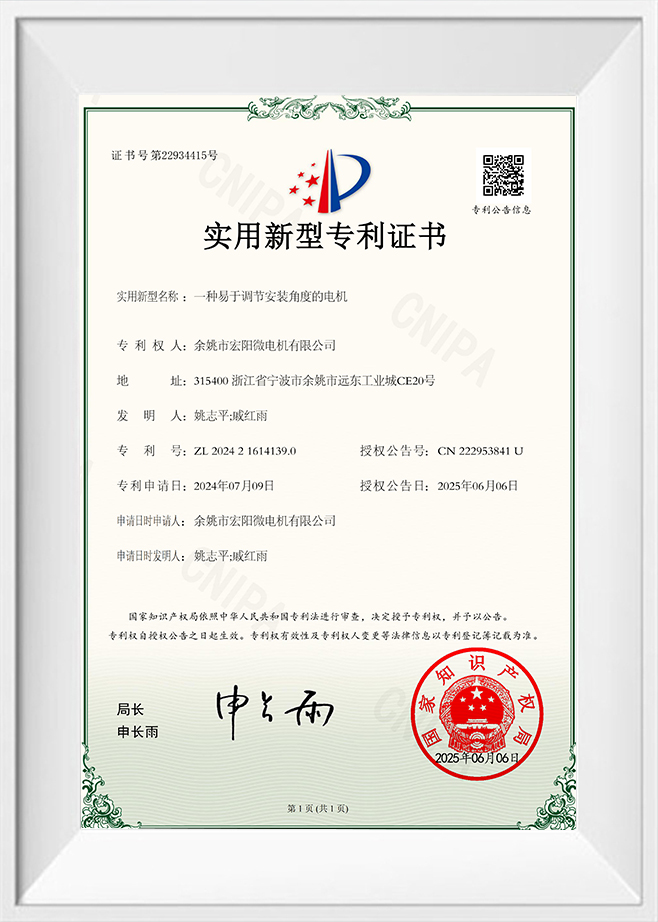

In the competitive global market of miniature motors, the ability to scale production without losing the touch of customization is what sets a leader apart. Yuyao Hongyang Micromotor Co., Ltd. maintains a leading position by bridging the gap between bespoke engineering and mass manufacturing. With an annual production capacity exceeding 10 million units, we possess the infrastructure to fulfill high-volume orders for global distributors while maintaining the flexibility to tailor solutions for specific client needs. Whether it is adjusting the shaft length, modifying the voltage range, or enhancing the EMI suppression, our “customer first” philosophy drives every project.

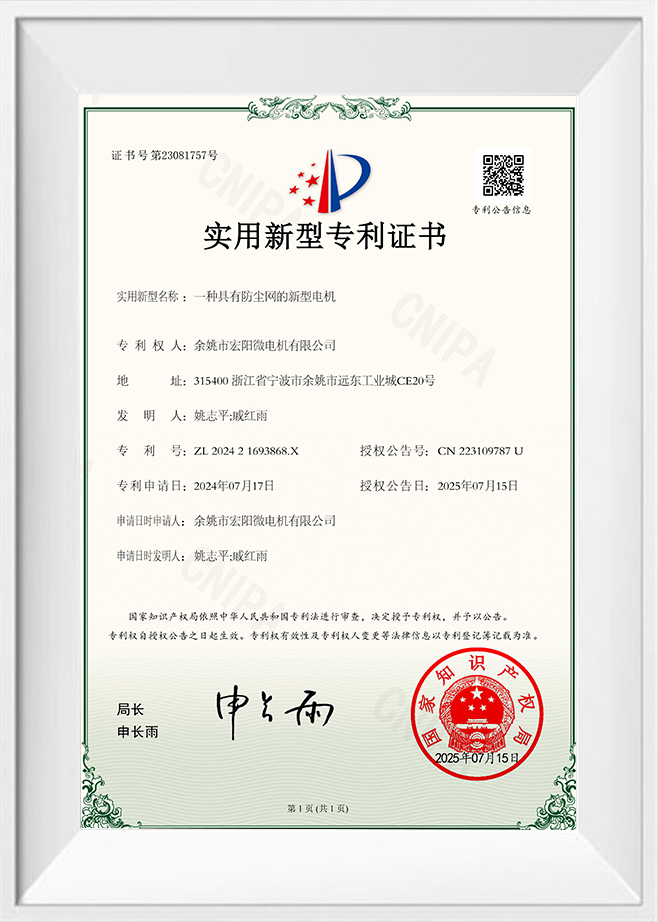

Our product portfolio—spanning the 300, 500, 700, 800, and 900 series—is designed to cover the full spectrum of industrial and consumer needs. For instance, the 700 and 800 series are ruggedized powerhouses frequently used in high-demand applications like garden power tools and industrial pumps. These motors must operate in harsh environments, resisting dust, moisture, and temperature fluctuations. To ensure reliability, Hongyang utilizes advanced testing laboratories where motors undergo rigorous stress tests, including life-cycle analysis and load testing. This commitment to quality is backed by our compliance with international standards such as ISO 9001, RoHS, and REACH, guaranteeing that our products are not only powerful but also safe and environmentally responsible for the global market.

The secret to our rapid delivery and customized design lies in our state-of-the-art production facilities. Automation plays a key role in our assembly lines, reducing human error and ensuring consistency across millions of units. However, the human element remains irreplaceable in our R&D department. Our engineers work closely with clients to understand the nuances of their applications. Are the motors being used in a smart home lock that requires high torque for short bursts? Or are they powering a medical pump that needs constant, pulse-free rotation? By integrating these insights into our design phase, Yuyao Hongyang Micromotor Co., Ltd. provides more than just a component; we provide a customized kinetic solution that enhances the end-user experience.

Future Horizons: The Role of Mini DC Motors in IoT and Smart Technology

As we look toward the future of technology, the definition of “miniature” continues to shrink. The rise of the Internet of Things (IoT), wearable health monitors, and smart home automation has created a massive demand for Mini DC Motors that are smaller, quieter, and more energy-efficient than ever before. Yuyao Hongyang Micromotor Co., Ltd. is uniquely positioned to lead this charge, leveraging our 30+ years of experience to innovate within the micro-motor space. Our mini motors are increasingly found in the “silent” corners of the modern home—driving the motorized curtains, operating the precision valves in smart faucets, and providing the haptic feedback in advanced gaming controllers.

The challenge of the mini motor lies in the delicate balance of efficiency and size. As motors get smaller, the mechanical tolerances become tighter, and the margin for error disappears. At Hongyang, our technical teams utilize advanced simulation software to predict motor behavior before a single prototype is built. This rapid prototyping capability allows our clients to bring their products to market faster, a crucial advantage in the fast-paced consumer electronics sector. Our mini motors are engineered to consume minimal power, extending the battery life of portable devices—a critical factor for the “unplugged” world of today.

Beyond simple rotation, the integration of Mini DC motors into robotics and automotive parts represents the next frontier. In the automotive sector, mini motors control everything from side-mirror adjustments to seat lumbar support and headlight leveling. These applications require absolute reliability over thousands of cycles. Yuyao Hongyang Micromotor Co., Ltd. ensures this reliability through a “zero-defect” quality control culture. By maintaining a complete industrial chain, we can trace every component back to its source, ensuring that the precision we promise is the precision we deliver. As we continue to develop professional services and tailor-made solutions, our commitment remains the same: to provide the world with the highest quality miniature motors, built on a foundation of experience and driven by the spirit of innovation.

Eng

Eng  русский

русский Español

Español